Products

Singi™

Low Dk/Df Siloxane PCB Resin/Film

SingiTM is the low dielectric constant(Dk)/dissipation factor(Df) thermosetting resin and glass-fabric reinforced pre-preg film based on the siloxane chemical. They can apply to high frequency (microwave) applications such as 5G/6G communication, RADAR sensor in automobiles, large-capacity high-speed electronic substrates, and bonding/build-up film semiconductor packaging. The fabricated Cu Clad Lamination (CCL) is used for 5G/6G communication PCB and antenna.

Features

- Low dielectric constant(Dk=2.92 @10 GHz)/dissipation factor(Df=0.0016 @10 GHz)

- High heat/humid stability No change in dielectric properties

- Direct lamination and good adhesion with Cu foil

- No halogen (fluorine) content and low carbon content

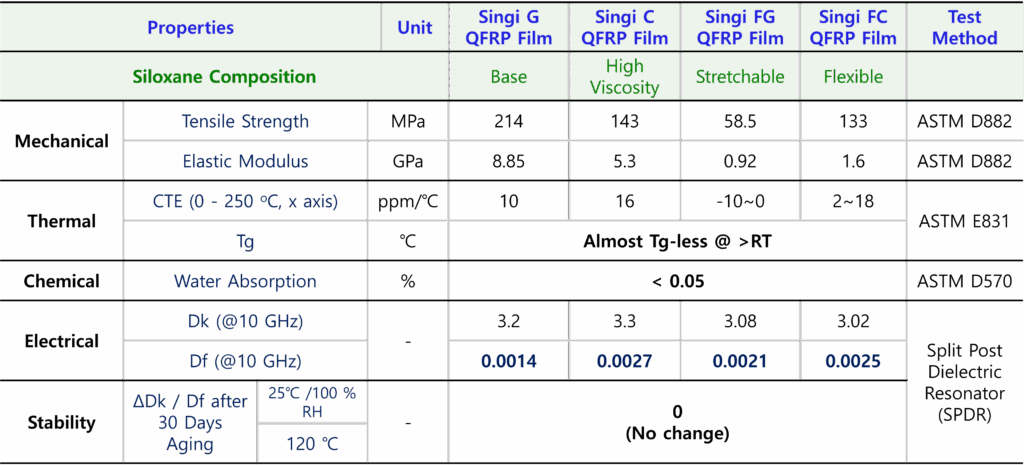

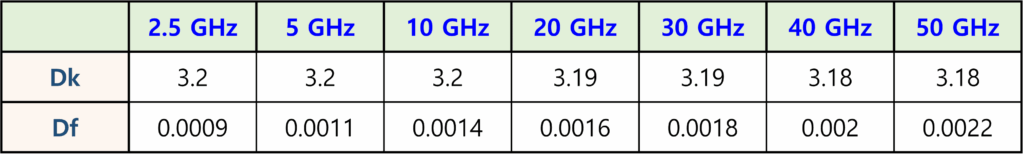

- Quartz-fabric Reinforced Pre-preg (QFRP) film Dk=3.2, Df=0.0014 @10 GHz CTE : ~10 ppm/oC

Singi™G

Base siloxane formulation with the lowest Dk/Df

Curing Condition

- 200℃ – 250℃ in inert atmosphere for > 2hrs

Specification (Resin Film)

- Dk = 2.92, Df = 0.0016 @ 10 GHz

- CTE : ~80ppm/℃ (0℃~250℃), No glass transition

- Tensile strength : 29 MPa, Elastic modulus : 1.4GPa, Elastic strain : ~2%

Specification (QFRP Film)

- Quartz-fabric Reinforced Prepreg (QFRP) Film

- Dk = 3.20, Df = 0.0014 @ 10 GHz

- CTE : ~10ppm/℃ (0℃~250℃)

- Tensile strength : 214 MPa, Elastic modulus : 8.9 GPa, Elastic strain : ~3.0 %

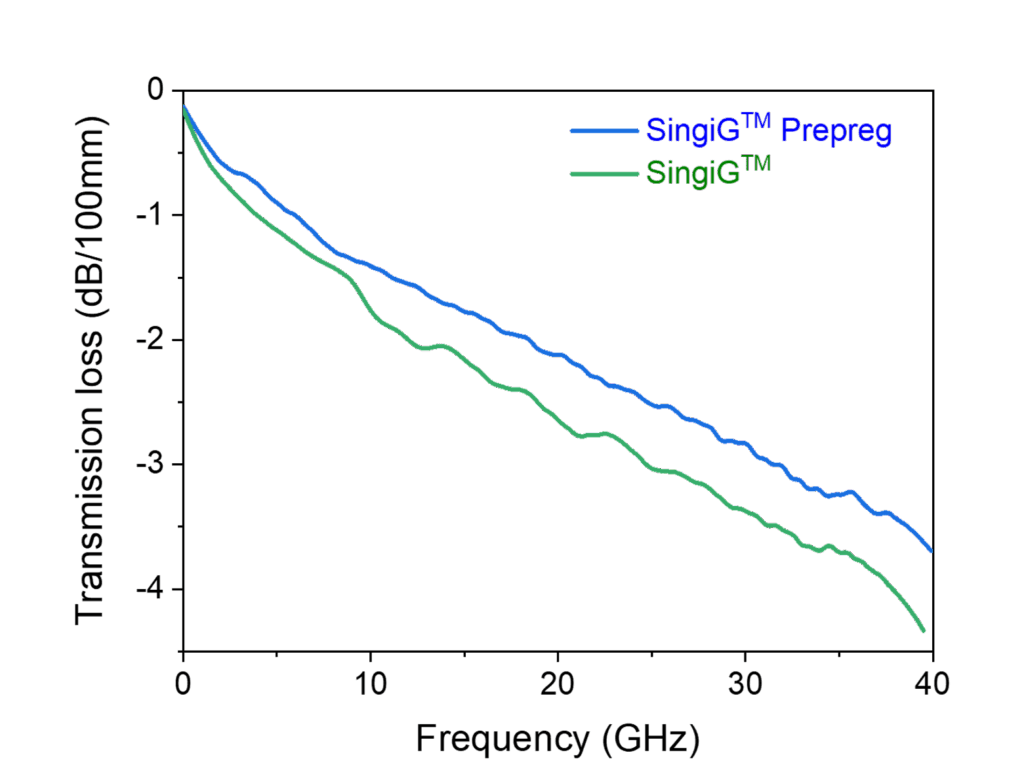

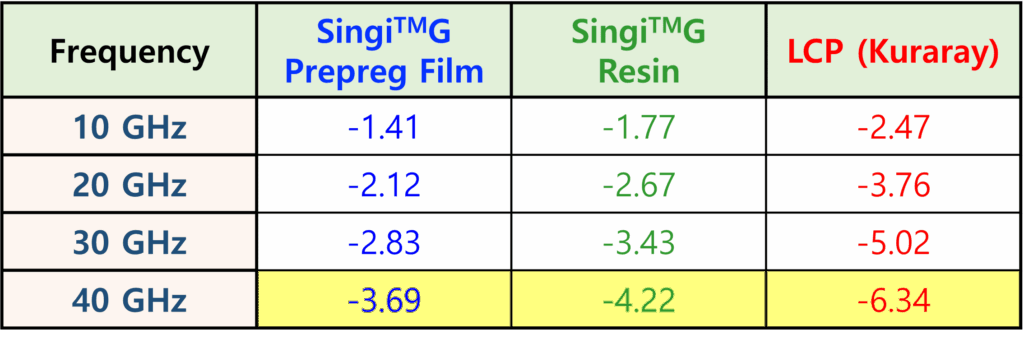

Microwave Transmission Characteristics

Transmission Loss (dB/100mm)

* LCP data from Kuraray VECSTARTM Brochure

Singi™C

High-viscosity siloxane formulation for B-stage prepreg film

Curing Condition

- 200 ℃ – 250 ℃ in inert atmosphere for > 2hrs

Specification (Resin Film)

- Dk = 2.92, Df = 0.0016 @ 10 GHz

- CTE : ~80ppm/℃ (0℃~250℃), No glass transition

- Tensile strength : 29 MPa, Elastic modulus : 1.4GPa, Elastic strain : ~2%

Specification (QFRP Film)

- Quartz-fabric Reinforced Prepreg (QFRP) Film

- Dk = 3.20, Df = 0.0014 @ 10 GHz

- CTE : ~10ppm/℃ (0℃~250℃)

- Tensile strength : 214 MPa, Elastic modulus : 8.9 GPa, Elastic strain : ~3.0 %

Singi™F

Stretchable Low Dk/Df Siloxane Elastomer

Singi™F is the highly elastic, stretchable low Dk/Df siloxane formulation suitable for use in foldable FPCB or semiconductor packaging substrates/films

Singi™F Series

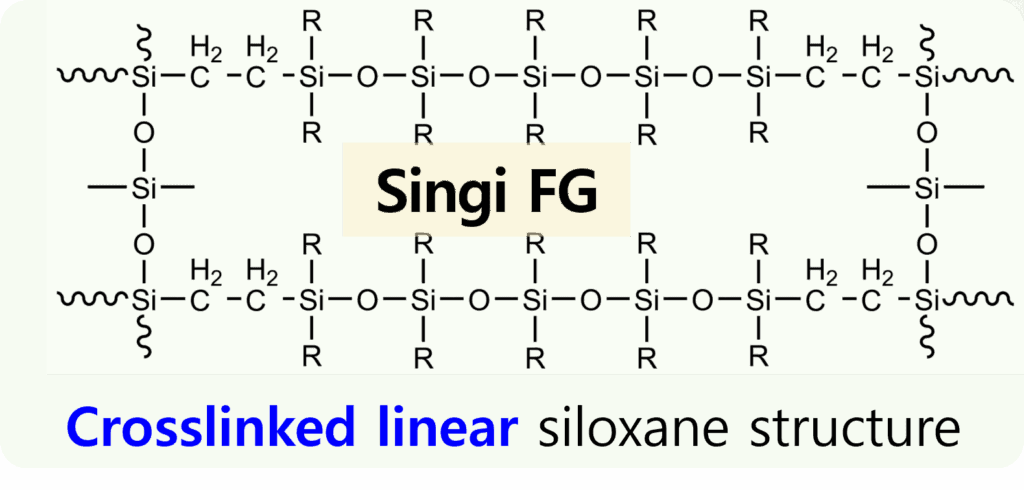

1. Singi™FG

- Highly Elastic low Dk/Df siloxane with crosslinked linear chemical structure

- Glass-Rubber transition at 20℃

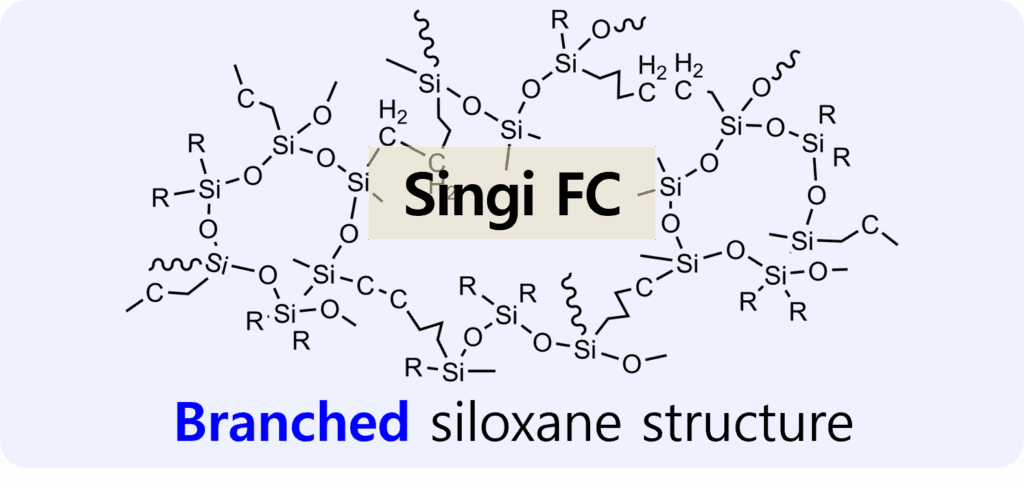

2. Singi™FC

- Highly Elastic low Dk/Df siloxane with branched chemical structure

- Glass-Rubber transition at 70℃

Features

- Low modulus and high elastic strain (stretchable/flexible)

- Low Dk/Df in the microwave frequency region

- Zero/tunable CTE glass-fabric reinforced prepreg (GFRP) film for applications to PCB and semiconductor packaging substrates/films

- Bonding characteristics of prepreg film and siloxane resin for simpler multi-layer PCB production and build-up film

- Application to highly foldable FPCB and advanced stress–free semiconductor packaging

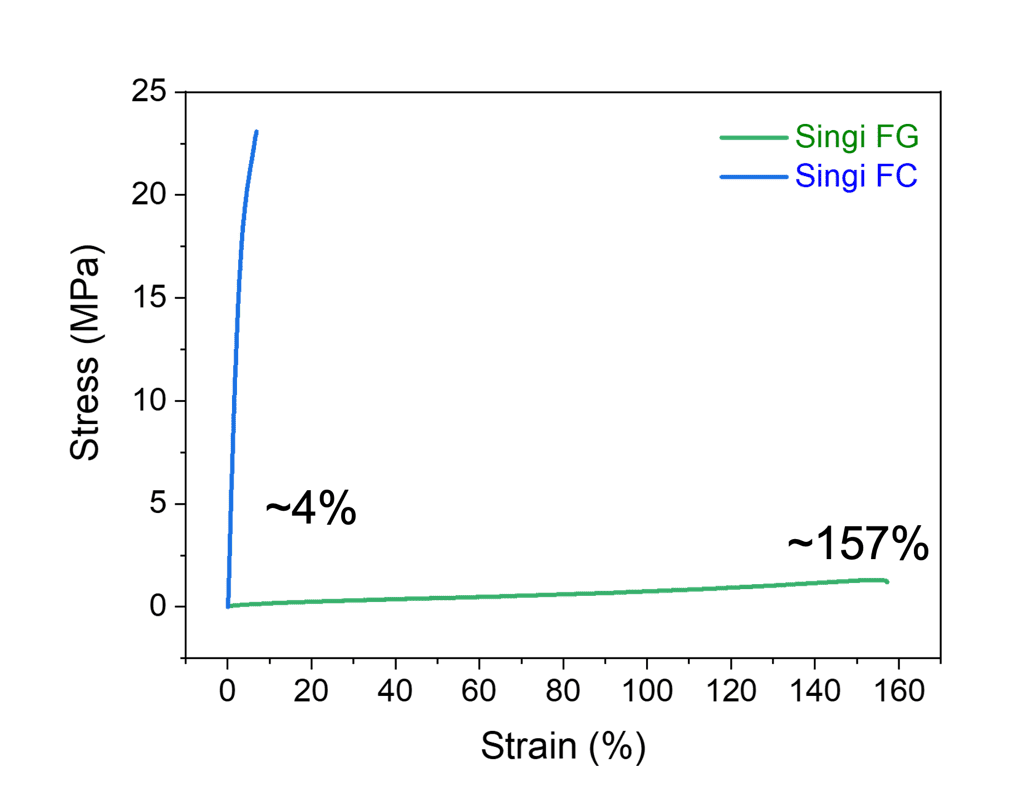

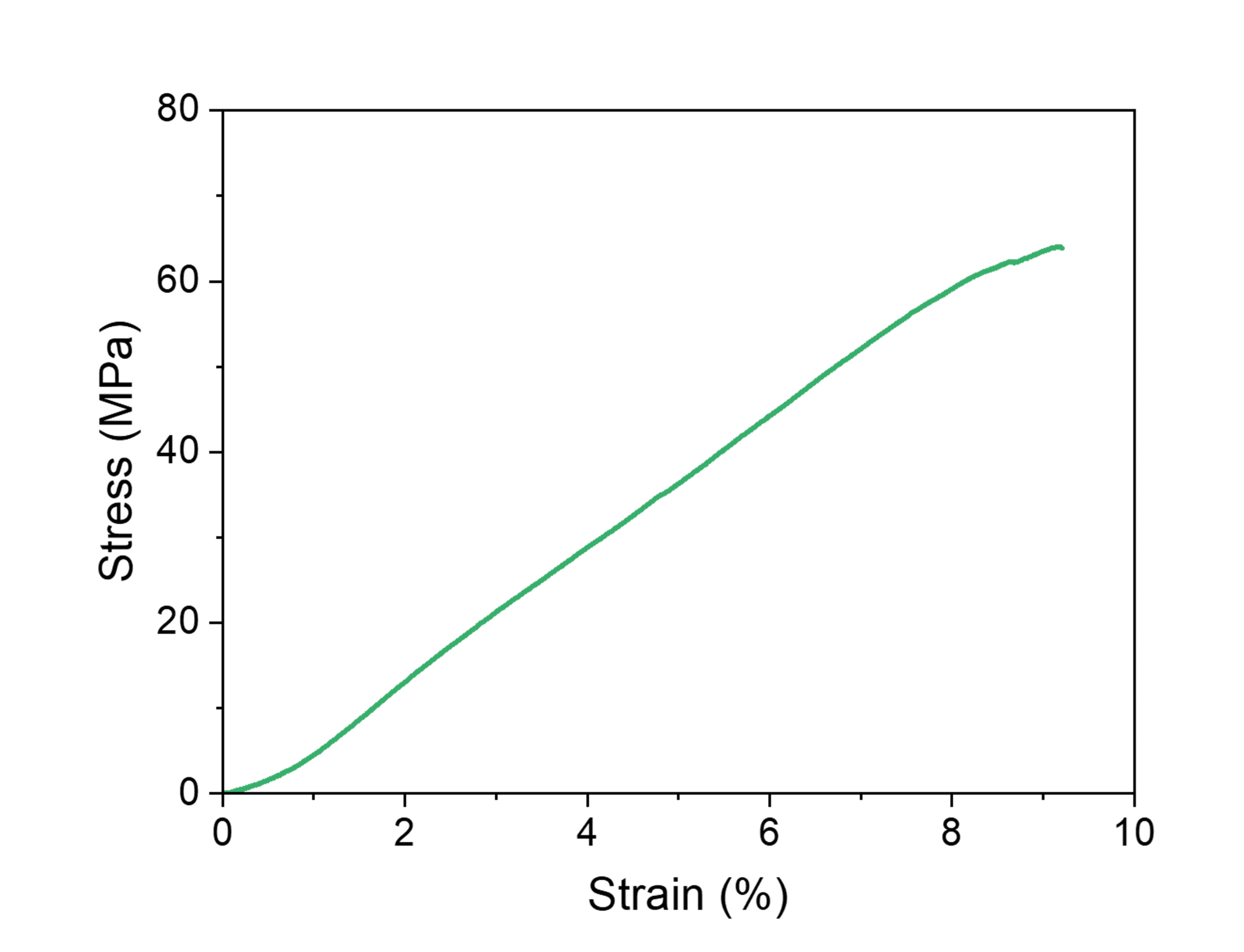

Tensile Test

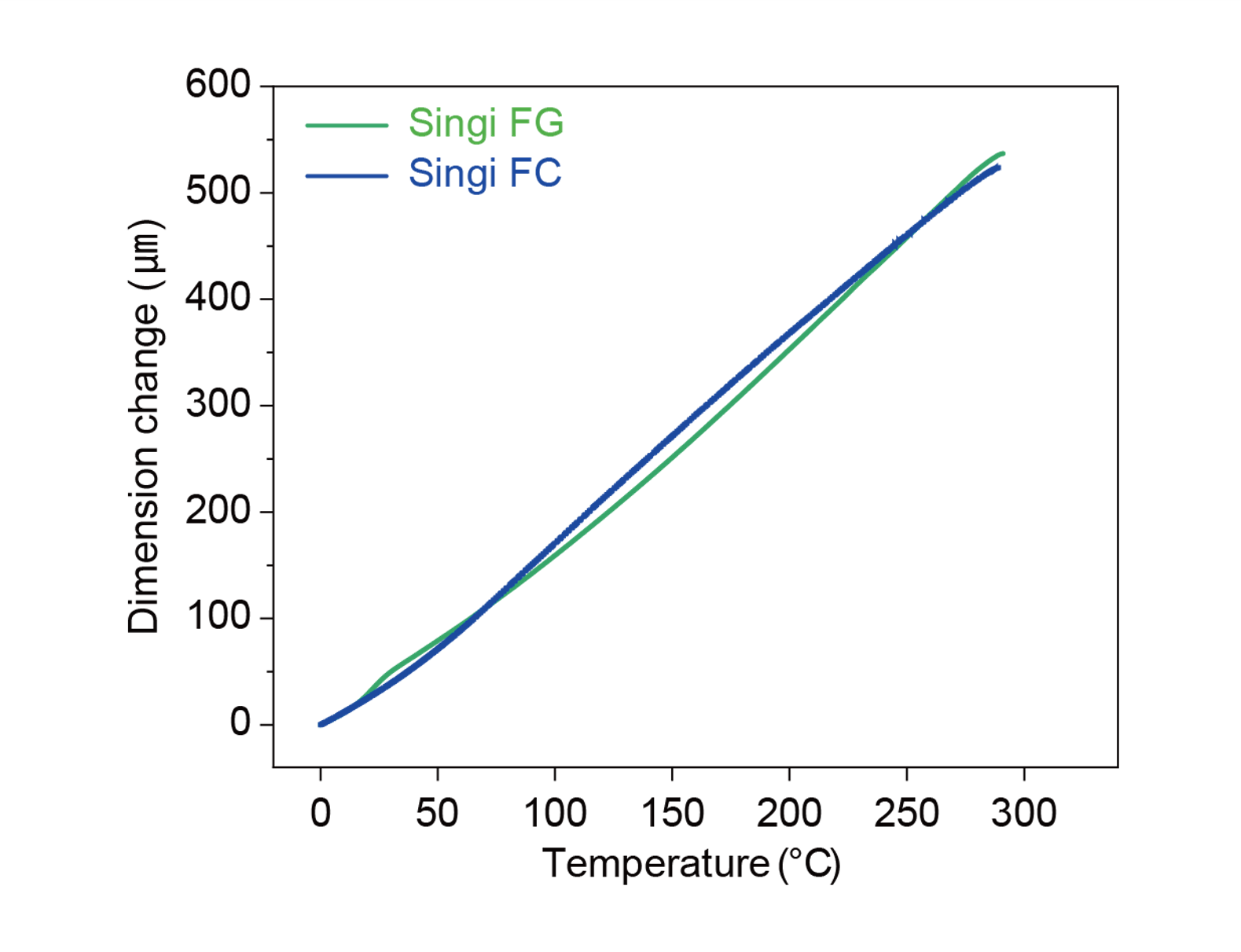

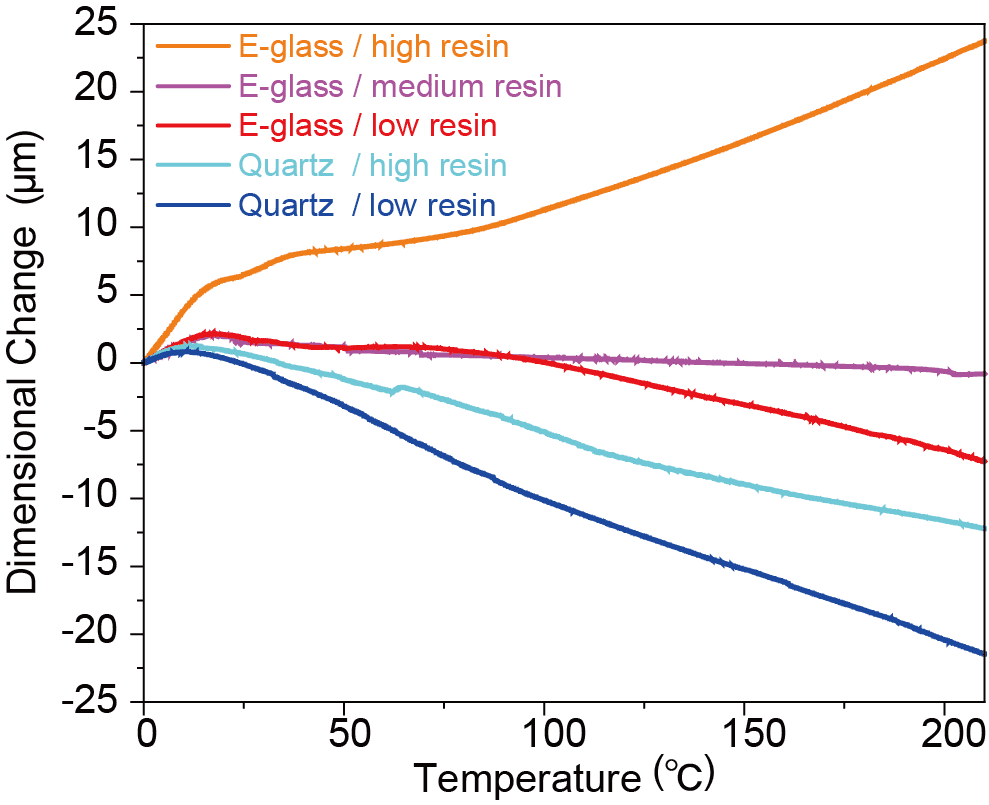

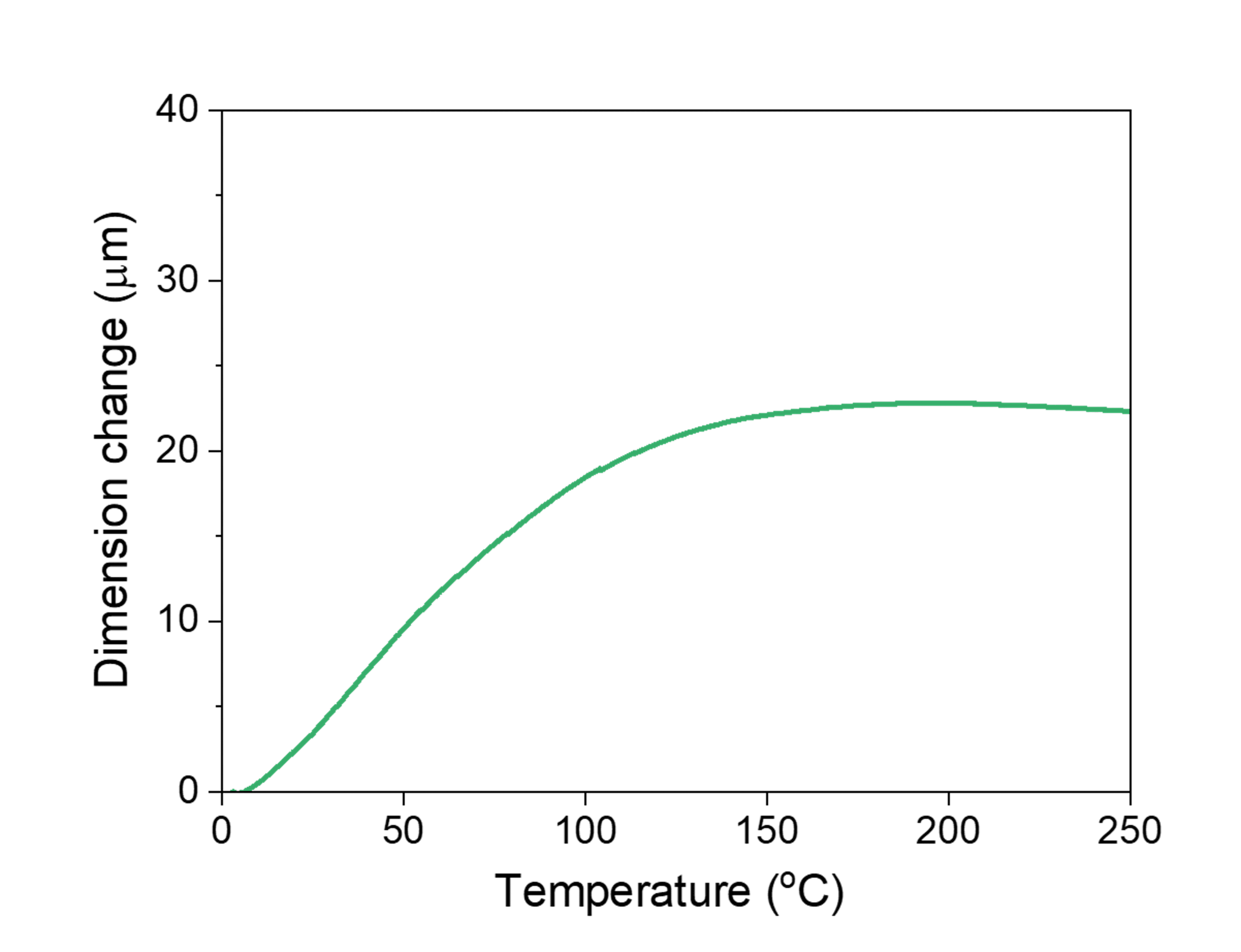

Thermal Expansion

Singi™FG

Stretchable siloxane elastomer formulation

Curing Condition

- 200 ℃ in air for > 2hrs

- Lower temperature curing in air

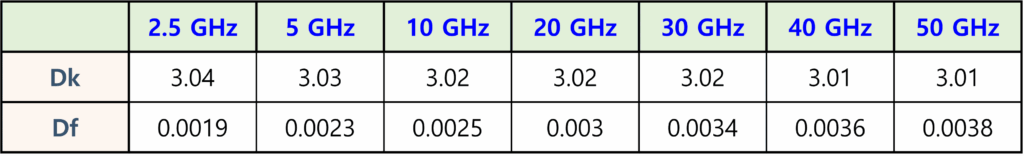

Dielectric Properties

- SingiTM FG : Dk = 2.90, Df = 0.0022 @ 10 GHz

- SingiTM FC : Dk = 2.92, Df = 0.0025 @ 10 GHz

Specification (QFRP Film)

~40mm film with quartz-fabric (Shinetsu SQ, 30mm), ~50% resin content

Tensile Test (QFRP Film)

Thermal Expansion (QFRP Film)

- Tensile strength : 58.5 MPa

- Elastic modulus : 923 MPa

- Elastic strain : ~10%

- CTE (<150C): -10 ~10 ppm/C

(depends on glass-fabric and resin content)

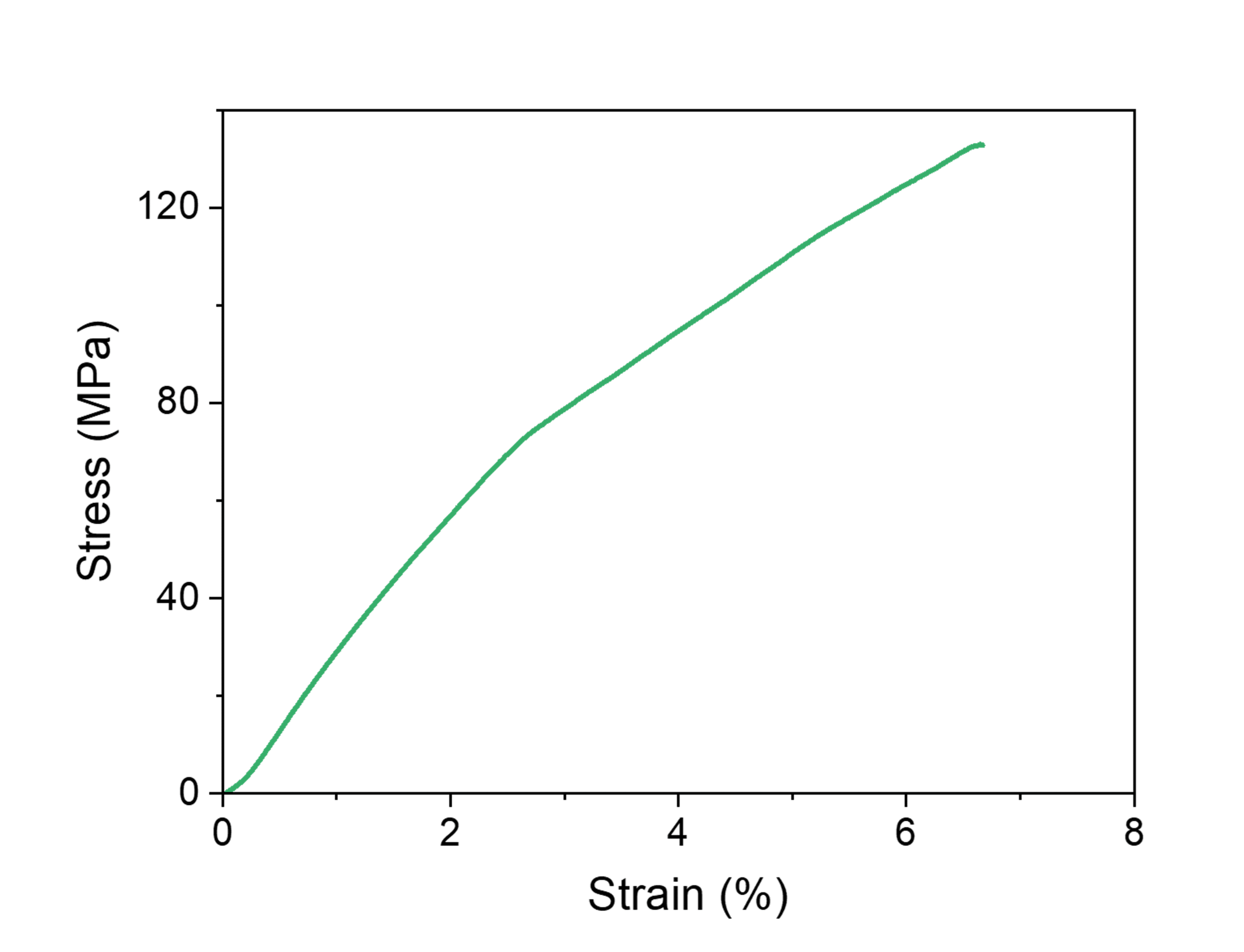

Singi™FC

Flexible siloxane elastomer formulation

Specification (QFRP Film)

~40mm film with quartz-fabric (Shinetsu SQ, 30mm), ~50% resin content

Tensile Test

- Tensile strength : 133 MPa

- Elastic modulus : 1.6 GPa

- Elastic strain : ~7%

Thermal Expansion

- CTE (<150C): 18ppm/C

- CTE (>150C) : 2ppm/C

- Transition at 80C~150C

Microstrip line coupon

~40mm film with quartz-fabric (Shinetsu SQ, 30mm), ~50% resin content

Multilayer FPCB manufacture

~40mm film with quartz-fabric (Shinetsu SQ, 30mm), ~50% resin content

Singi™ Prepreg Specifications